1. Design Methodology for Centrifuge Pump

|

|

|

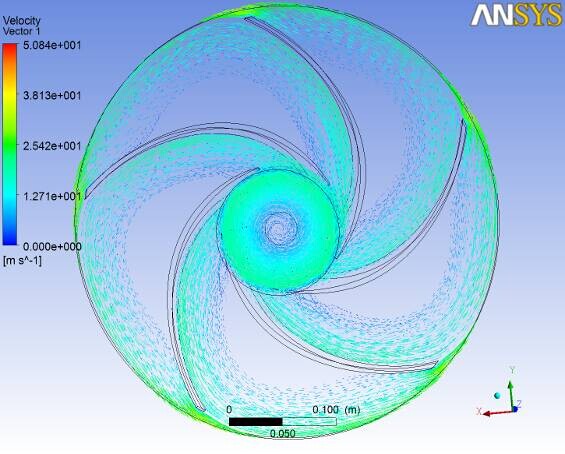

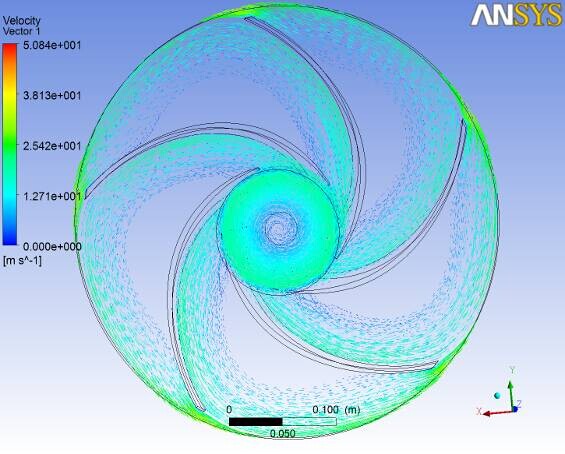

(a) Absolute Velocity Sector Diagram

|

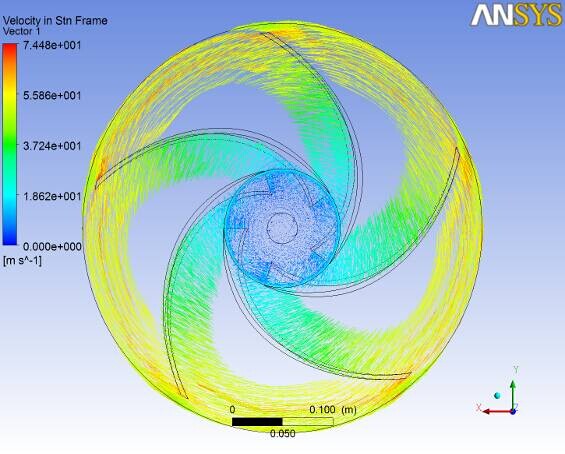

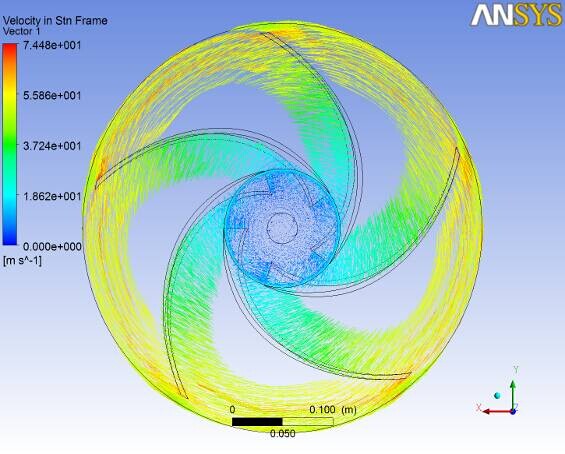

(b) Relative Velocity Sector Diagram

|

|

Fig 1: Flow Vector Diagram in Designed Impellor

|

|

|

|

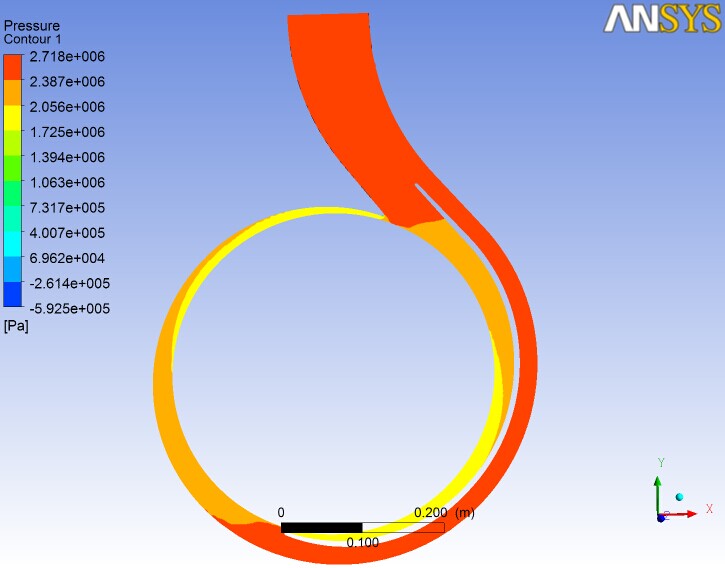

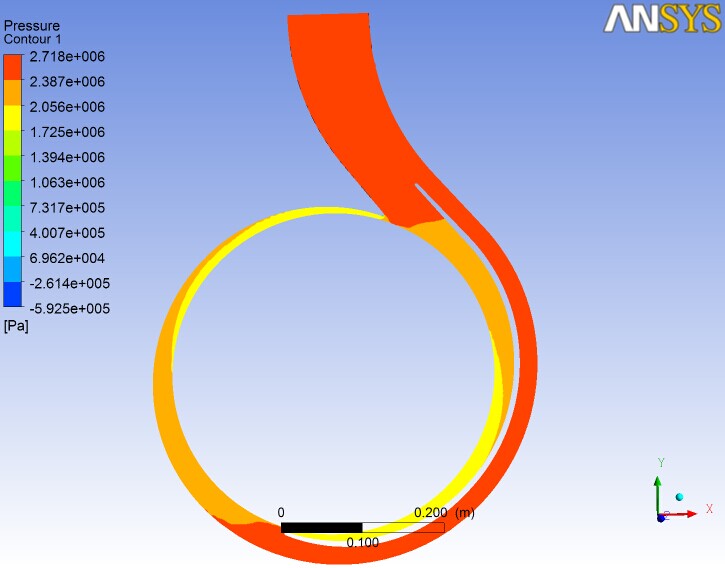

(a) Mid Section of Static Pressure Diagram of Volute |

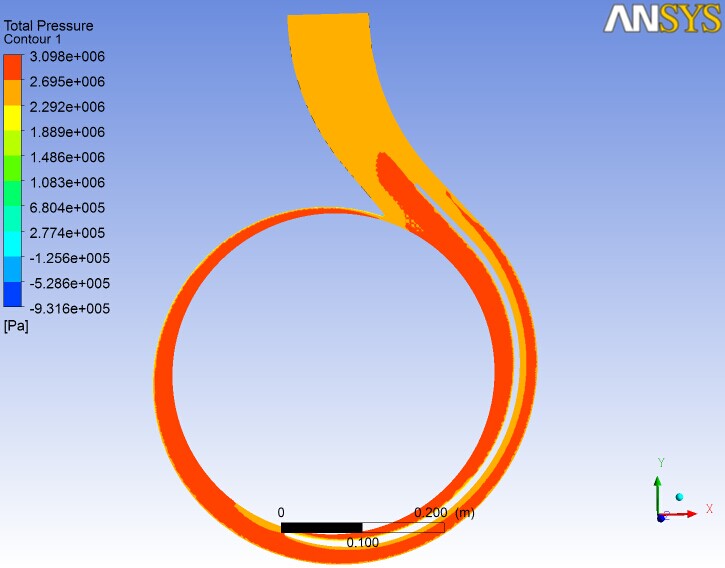

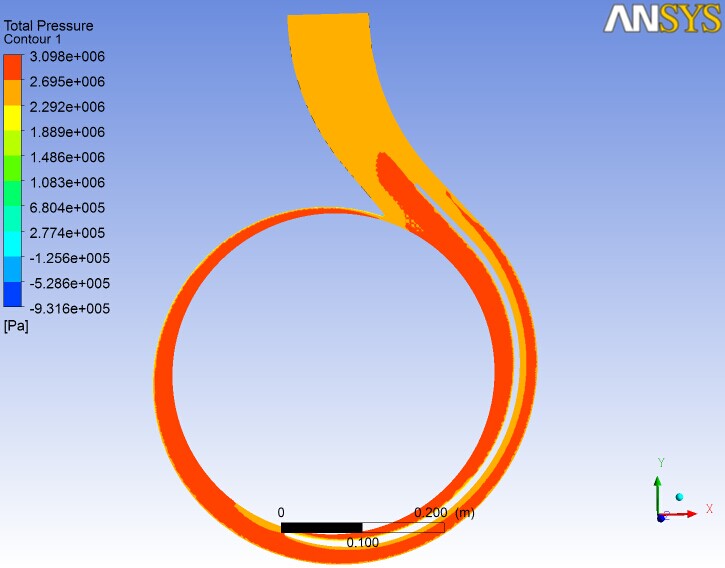

(b) Mid Section of Total Pressure Diagram of Volute

|

|

Fig 2: Diagram of Static Pressure and Total Pressure of Designed Volute |

Single stage centrifuge pump:Moudle: 4HPX15A Flow Rate: 200m3/hr,Rotating Speed: 3583rpm, Power: 225KW, Range of lift: 278—294m. CCS Certified.2、Pump Manufacturing:

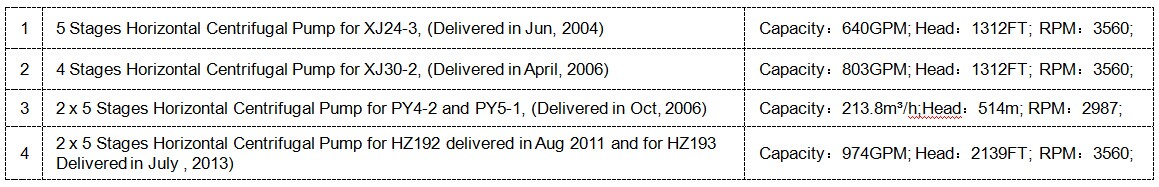

Tracked well operating Multi-Stage Pumps manufacture by us:

3. Transfer Centrifugal Pump for subsea pipeline preheat on XJ24-3 and P-2407, Anping Project

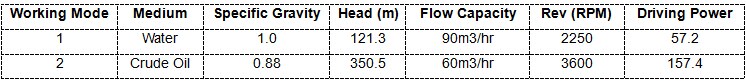

Pump Performance Data:

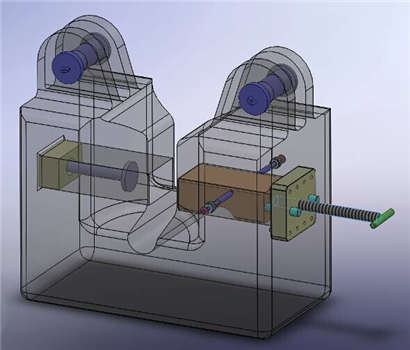

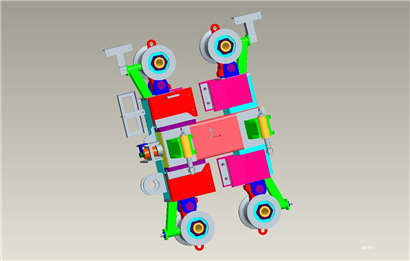

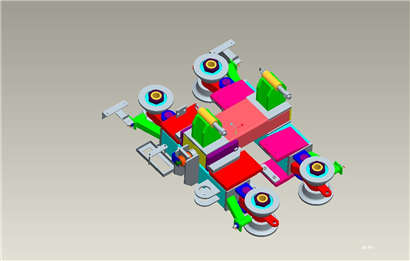

Pump Skid Manufacture

Skid and pump Design, manufacture, testing, CSS Certify, and FAT; Diesel Engine Driven, with transmission box, API Standard.

|

|

Pump Skid for XJ24-3 and P-2407, Anping Project |

4. Anchor Weight Manufacture for POC

5. Offloading Hose Floating Buoy Manufacture:

|

|

|

Fabrication Process for Floating Buoy |

Offloading Hose Floating Buoy

|

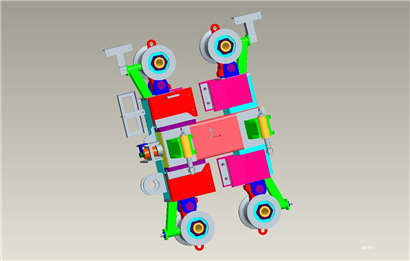

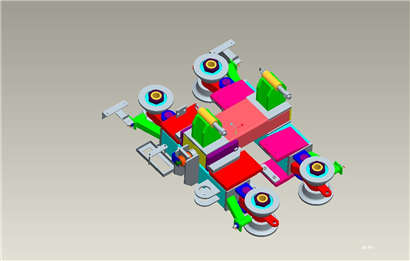

6. Drilling Top Driver Guide Dolly Farbication

|

|

|

3D View of Guide Dolly |

|

|

|

Guide Dolly Assembly |

|

|

|

|

Hydrualic Hose Reel Test |

|

|

|

|

Hydrostatic Test |

Pack & Delivery |